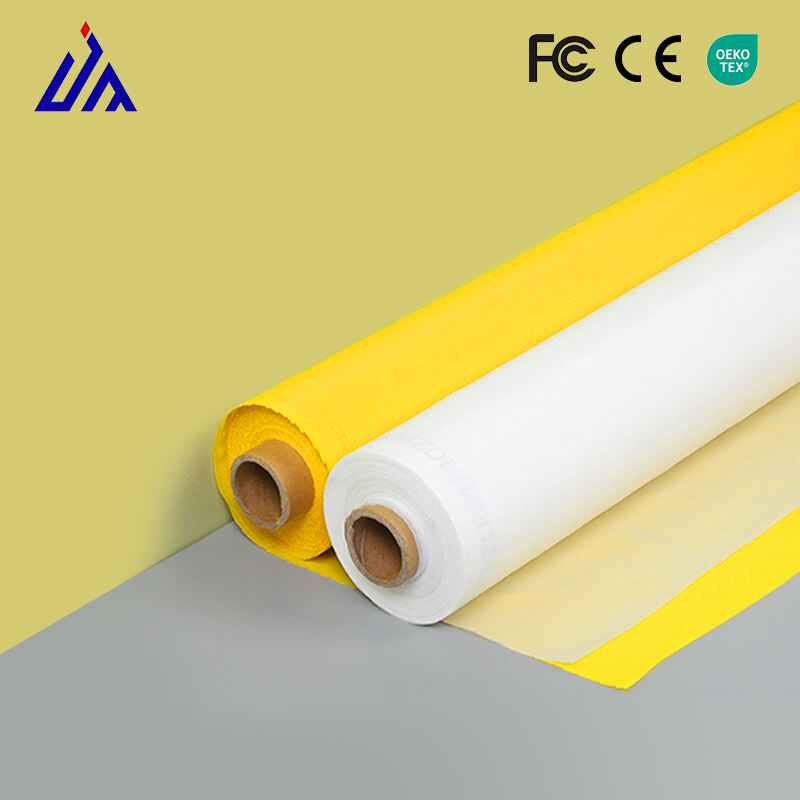

110 mesh silk screen

The 110 mesh silk screen is a precision-engineered printing mesh that serves as a fundamental component in screen printing applications. This specialized mesh features 110 threads per inch, creating a balanced structure that offers optimal ink flow and image resolution. The mesh is typically constructed from high-grade polyester threads, woven together in a precise pattern to ensure consistent performance and durability. The 110 count provides an ideal middle-ground mesh that can handle various printing applications, from textile printing to industrial marking. The screen's thread diameter and mesh opening are carefully calculated to achieve the perfect balance between ink deposit and detail retention. This mesh count is particularly effective for printing medium to large graphics, solid areas, and general purpose applications. The structure allows for excellent ink release while maintaining proper tension stability, making it suitable for both manual and automatic printing processes. The mesh's design also incorporates specific thread thickness and weave patterns that help prevent common printing issues such as moiré patterns and inconsistent ink coverage. With its versatile nature, the 110 mesh silk screen has become a standard choice for printers working with various substrates, including fabrics, plastics, and paper products.