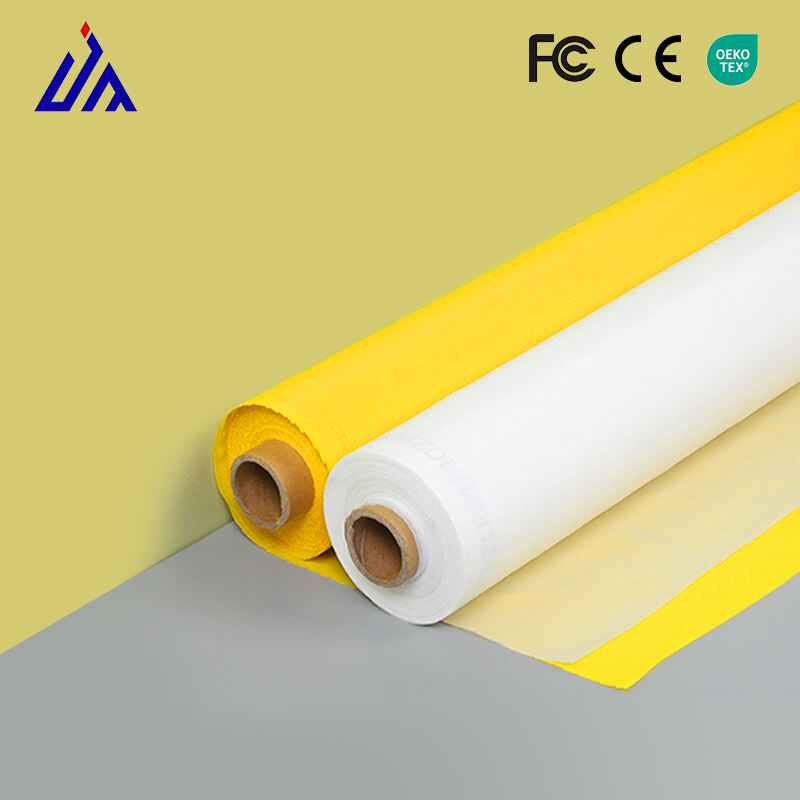

screen printing mesh

Screen printing mesh serves as a crucial component in the screen printing process, functioning as a precision-engineered fabric that enables the transfer of ink onto various substrates. This specialized mesh is typically manufactured from high-grade polyester or stainless steel threads, woven into precise patterns with specific thread counts per inch. The mesh's primary function is to hold the stencil design while allowing ink to pass through in controlled amounts, ensuring accurate image reproduction. The technological features of screen printing mesh include carefully calibrated thread diameters, precise mesh openings, and specific tension characteristics that maintain dimensional stability during printing. Available in various mesh counts ranging from coarse to ultra-fine, each type is designed to accommodate different printing requirements, from basic textile printing to sophisticated electronic circuit printing. The mesh's construction also incorporates special surface treatments that enhance ink release and prevent mesh clogging, contributing to consistent print quality and extended screen life. In industrial applications, screen printing mesh is essential for producing everything from printed circuit boards to solar panels, while in commercial printing, it enables the creation of high-quality graphics on products ranging from t-shirts to vehicle wraps.