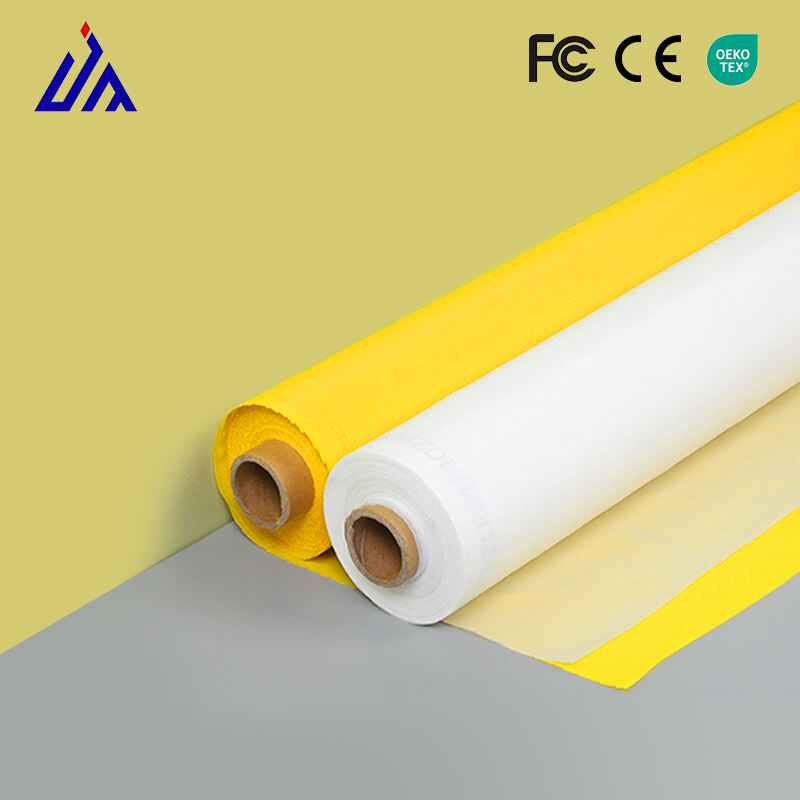

110 mesh for screen printing

The 110 mesh for screen printing represents a versatile and widely used mesh count in the screen printing industry, characterized by its balanced thread count of 110 threads per inch. This medium-range mesh count offers exceptional versatility for various printing applications, making it an ideal choice for both beginners and experienced printers. The mesh's structure features precisely woven polyester threads that create consistent openings, allowing for controlled ink deposit and excellent detail reproduction. The 110 mesh strikes an optimal balance between ink flow and detail retention, making it particularly effective for printing on textiles, paper, and other common substrates. The mesh's construction provides sufficient stability to maintain proper tension during the printing process while allowing adequate ink transfer to achieve solid coverage. Its technical specifications typically include a thread diameter of around 31 microns and an opening size of approximately 200 microns, which enables it to hold and transfer ink effectively without clogging. This mesh count is particularly well-suited for printing with plastisol inks, water-based inks, and various specialty formulations, offering consistent results across multiple printing runs. The durability of the 110 mesh ensures extended service life when properly maintained, making it a cost-effective choice for print shops of all sizes.