Dtf printer is called direct to film printer which is a unique printing technology that involves printing designs onto special PET films for transfer onto to a variety of garments (and other substrates). DTF printing machine is a heat transfer process that has the ability to last as long as traditional silkscreen prints. Below, you should know about DTF technology before implementing it in your business. When printing directly to a textile, your options are limited. DTF Printer gives you much more flexibility, as you can print on a variety of fabrics, including cotton, polyester, rayon, nylon, silk, leather, and more.

Hot Sale Large Format DTF Printer 24inch Width Dual Head Xp600 with Glue Shaker for T Shirt Printing

It is a high-performance DTF (Direct to Film) printer designed specifically for T-shirt printing and other textile applications. Features a built-in glue shaker and powder drying machine, ensuring efficient application of adhesive powder for heat transfer.

- Overview

- Recommended Products

Product Introduction

SPECIFICATION |

||||||

DTF digital Printer |

Powder shaker machine |

|||||

Printing width |

60cm-62cm |

Function |

Heating drying & curing system |

|||

Print head |

Epson XP600 / i1600 / i3200 |

Collecting system |

Automatic collection |

|||

Print speed |

4pass:16㎡/h 、6pass:13㎡/h、 8pass:10㎡/h |

Power |

3400W |

|||

Printing accuracy |

360*2400dpl、360*3600dpl、720*2400dpl |

Energy consumption |

1KW-2.5KW |

|||

Operating System |

Windows XP/7/8/10/11 |

Heating tube |

Adjustable |

|||

Ink color |

C M Y K +W |

Feeding material width |

60cm-62cm |

|||

Printing media type |

PET Transfer vinyl+Hot melt powder |

Dusting system |

Automatic |

|||

Voltage |

110V/220V |

Voltage |

220V/25A |

|||

Packing size |

1850x810x740mm |

Packing size |

1960x1290x950mm |

|||

G.W. |

190KG |

G.W. |

220KG |

|||

DTF Inkjet Printing machine

Wide Format 24 inches DTF Printer Package

DTF printing technology's strongest selling point would be it ablity to work on almost every type of fabric without the need for pre-treatment, while being able to product sharper and more vibrant colours.

Detail display

Product Usage

Operation

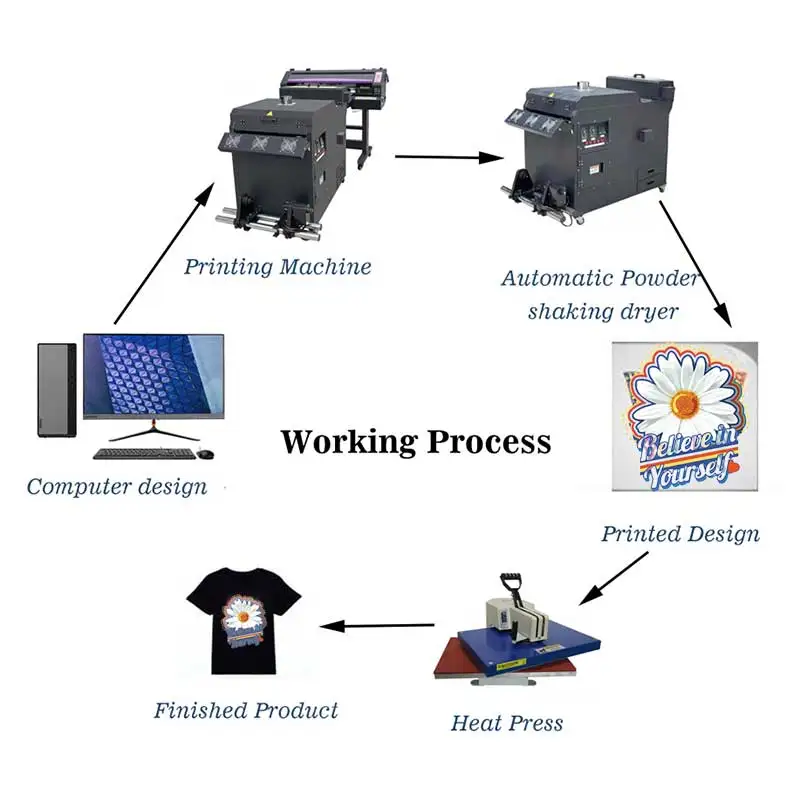

1. Use software draw the pictures , and then use the printer to print the pattern on the PET machine 2.Sprinkle an appropriate amount of hot melt poweron the printed PET film and shake off the excess hot melt power3. Put the PET film on the heat transfer machine and back for 5-7 minutes ,until the hot melt powder melts , take out the PET film4. Lay the T shirt flat on the heat transfer amchine and stick the sidesprinkled with hot melt powder on the T shirt for pattern hot samping and the hot stamping takes 15-20 seconds

Factory Display

FAQ

1. who are we?We are based in Shijiazhuang, China, start from 2013,sell to North America,Western Europe,Southeast Asia,Eastern Europe,Mid East. There are total about 100+ people in our company.2. How can we guarantee quality?Always a pre-production sample before mass production;Always final Inspection before shipment;3.What can you buy from us?Inkjet Printer (UV Printer,DTG Printer,DTF Printer,UV DTF Printer,T Shirt Printing Machine),Screen Printing machine and Screen printing materials4. Why should you buy from us not from other suppliers?1. We provide one-year warranty and lifetime service for customers.2. Accept third-party inspection service to guarantee quality and quantity for you.3. The product has Chinese design patent protection.4. Our products can be customized in the logo.5. What services can we provide?Accepted Delivery Terms: FOB,CIF,EXW,CIP,DEQ,DDP;Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;Language Spoken:English,Chinese