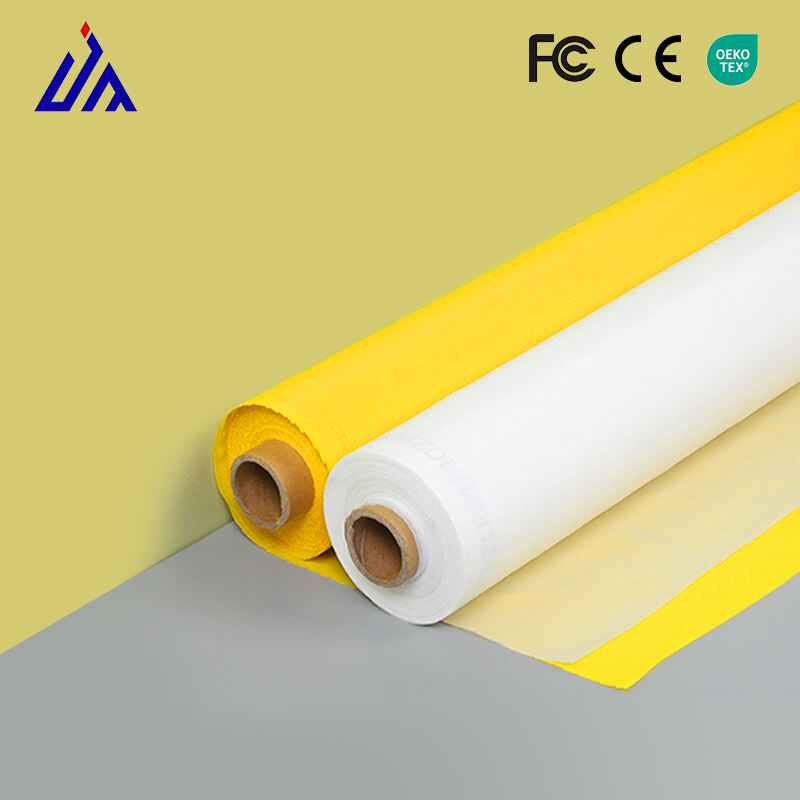

screen printing screen mesh

Screen printing screen mesh is a crucial component in the screen printing process, serving as the foundation for creating high-quality printed designs across various materials. This specialized mesh, typically constructed from polyester or stainless steel threads, features precisely woven patterns that determine the resolution and detail of the final print. The mesh count, which refers to the number of threads per inch, ranges from coarse (around 30-60 threads) to extremely fine (up to 500 threads), allowing printers to achieve different levels of detail and ink deposit. The mesh's construction involves a precise manufacturing process that ensures uniform tension, consistent thread spacing, and optimal ink flow characteristics. Modern screen printing meshes incorporate advanced surface treatments that enhance ink release and improve cleaning efficiency, making them more durable and cost-effective for commercial printing operations. These meshes are designed to maintain dimensional stability under tension and resist chemical deterioration from exposure to various ink types and cleaning solvents. The versatility of screen printing mesh enables its application across diverse industries, from textile printing and electronics manufacturing to automotive components and promotional products.