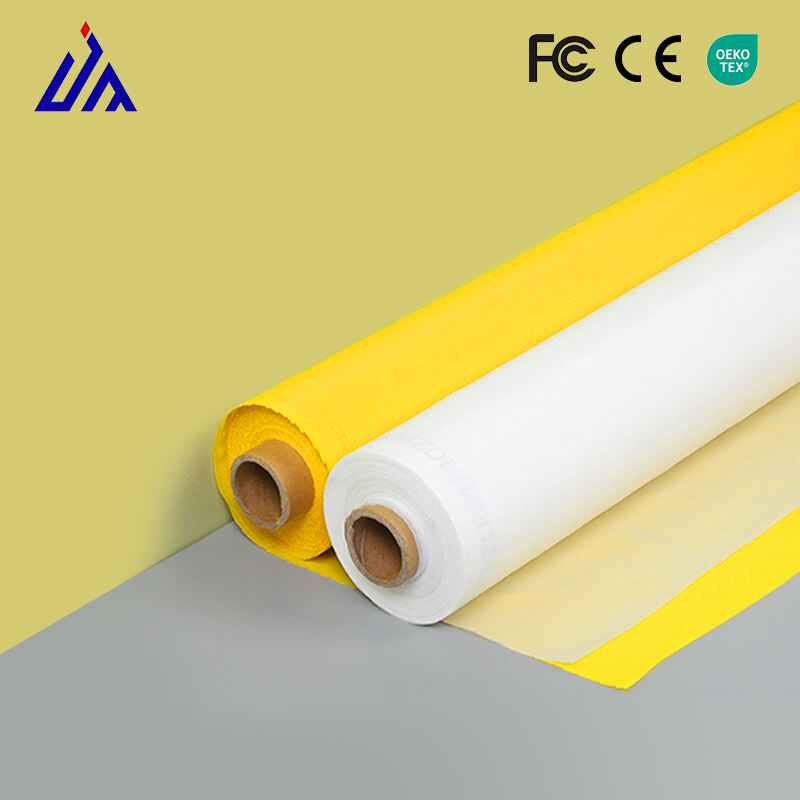

160 mesh screen

The 160 mesh screen represents a crucial filtration and separation solution widely used across various industries. This precision-engineered screen features 160 openings per linear inch, creating a finely woven mesh structure that effectively filters particles ranging from 88 to 100 microns. Made from high-grade stainless steel or synthetic materials, the 160 mesh screen offers exceptional durability and resistance to corrosion, making it ideal for demanding industrial applications. The screen's uniform wire diameter and precise opening sizes ensure consistent filtration performance, while its robust construction maintains structural integrity under high pressure and continuous operation. The 160 mesh screen excels in applications such as powder classification, liquid filtration, and material separation processes. Its balanced combination of flow rate and particle retention makes it particularly valuable in chemical processing, food and beverage production, pharmaceutical manufacturing, and water treatment facilities. The screen's ability to maintain consistent performance while handling various materials, from fine powders to liquid suspensions, demonstrates its versatility and reliability in industrial processes.