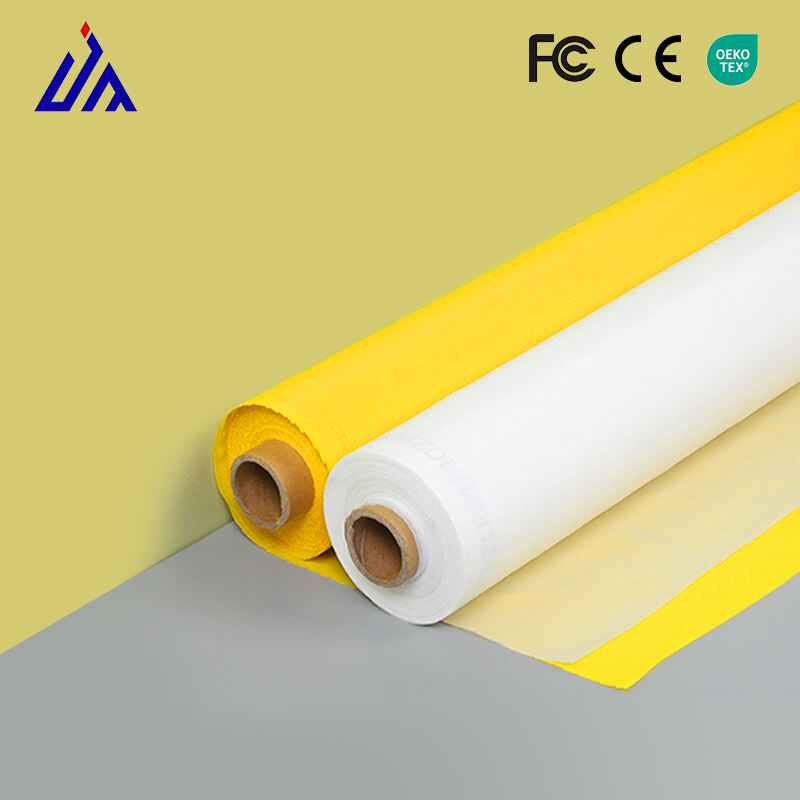

silk screening material

Silk screening material represents a versatile and essential component in the printing industry, serving as the foundation for creating precise and durable printed designs across various surfaces. This specialized material consists of finely woven mesh stretched over a frame, typically made from polyester or nylon, though traditionally silk was used. The material features precisely sized mesh openings that allow ink to pass through while maintaining sharp image definition. Modern silk screening materials incorporate advanced coating technologies that enhance durability and precision, with mesh counts ranging from 30 to 500 threads per inch to accommodate different printing requirements. The material's unique construction enables consistent ink deposit and excellent detail reproduction, making it ideal for both industrial applications and artistic endeavors. These materials often feature anti-static properties and specialized coatings that prevent ink bleeding and ensure clean, sharp prints. The technological advancement in silk screening materials has led to improved tear resistance, enhanced dimensional stability, and superior tension retention, ensuring consistent print quality throughout extended production runs.