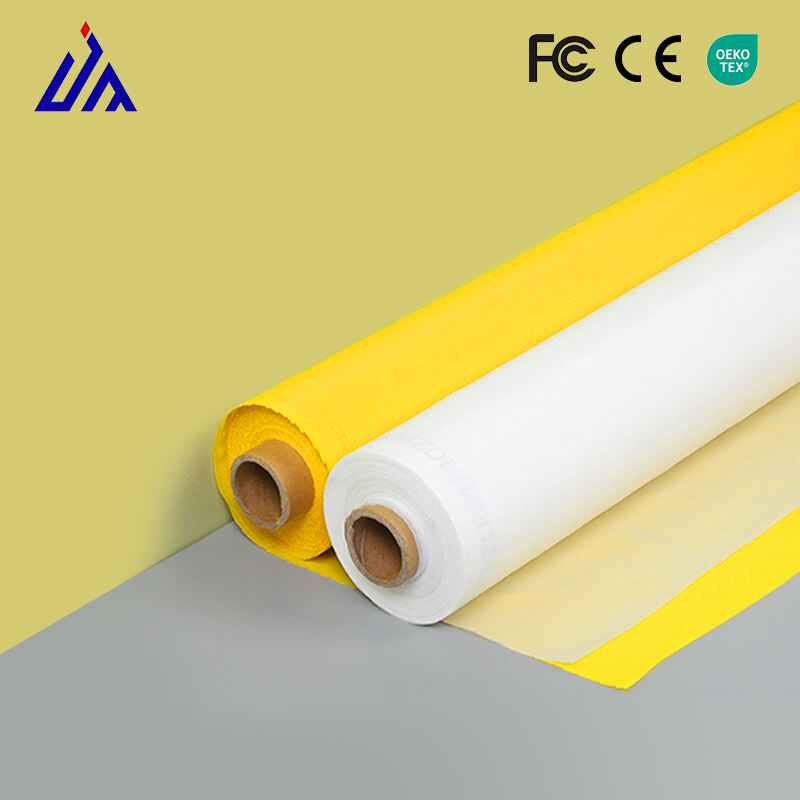

silk screen mesh

Silk screen mesh stands as a fundamental component in the screen printing industry, serving as a precision-engineered fabric that enables the transfer of ink onto various substrates. This specialized mesh, typically manufactured from high-grade polyester or stainless steel threads, features precisely calculated openings that control ink deposit and image resolution. The mesh count, which refers to the number of threads per inch, determines the fineness and detail capability of the printed image. Modern silk screen mesh incorporates advanced surface treatments that enhance ink release and maintain consistent tension throughout the printing process. The material's durability allows for repeated use while maintaining dimensional stability under various printing conditions. Its versatility accommodates applications ranging from textile printing and electronic circuit boards to automotive displays and artistic reproductions. The mesh's construction ensures uniform ink distribution, preventing common printing defects such as bleeding or pixelation, while its chemical resistance protects against degradation from various ink types and cleaning solvents.