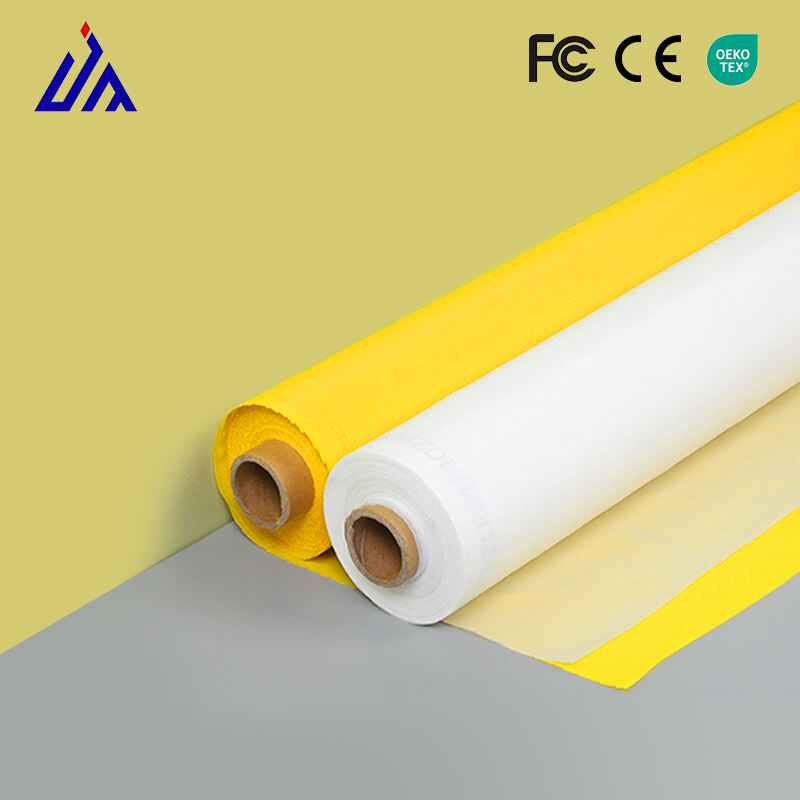

110 screen printing mesh

The 110 screen printing mesh stands as a fundamental component in the screen printing industry, offering a precise balance of mesh count and thread diameter for optimal printing performance. This professional-grade mesh features 110 threads per inch, making it particularly suitable for medium to large particle inks and applications requiring substantial ink deposits. The mesh is typically constructed from high-quality polyester threads, ensuring durability and maintaining consistent tension throughout the printing process. Its specific construction allows for excellent ink flow while maintaining image definition, making it ideal for printing on various substrates including textiles, ceramics, and industrial applications. The 110 mesh count provides adequate open area percentage, facilitating proper ink transfer while maintaining sufficient detail in the printed image. This mesh specification is particularly valued in applications requiring heavier ink deposits, such as printing with specialty inks, metallic colors, or when working with rougher printing surfaces. The structural integrity of the 110 mesh ensures minimal stretch and excellent recovery, contributing to consistent print quality across long production runs. Its versatility makes it a popular choice for both manual and automatic printing operations, offering reliable performance across various printing conditions and requirements.