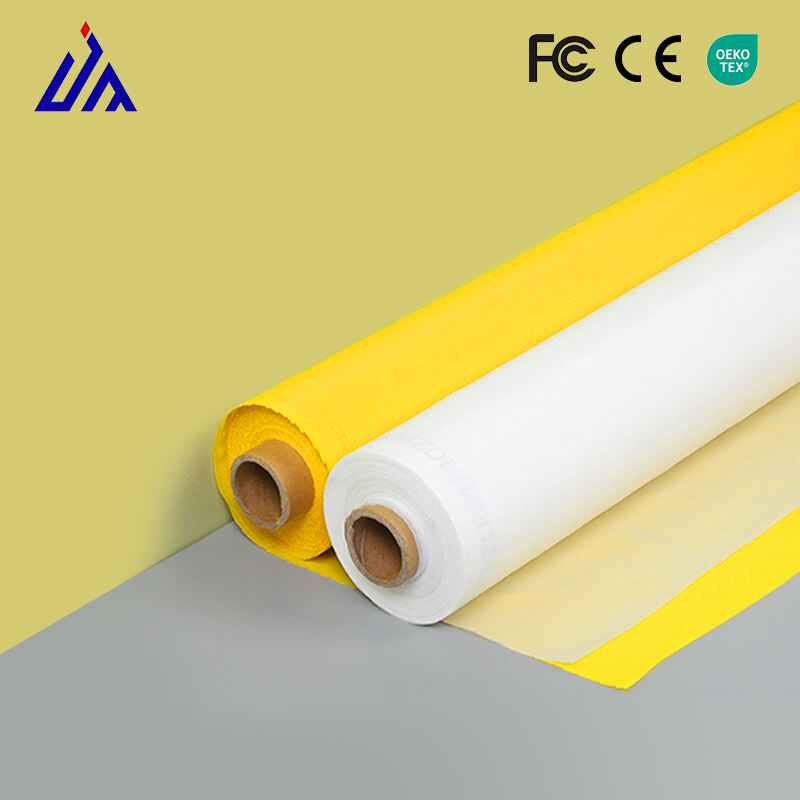

230 mesh screen

The 230 mesh screen represents a crucial component in industrial filtration and screening processes, offering precise particle separation capabilities with its carefully engineered mesh structure. This specialized screen features 230 openings per linear inch, creating a uniform grid pattern that ensures consistent filtration results. The screen's wire diameter and opening size are meticulously calculated to achieve optimal flow rates while maintaining exceptional particle retention. Manufactured using high-grade stainless steel or other durable materials, the 230 mesh screen demonstrates remarkable resistance to corrosion and wear, making it suitable for demanding industrial applications. Its precise construction allows for the efficient separation of particles down to approximately 63 microns, making it invaluable in industries such as chemical processing, pharmaceutical manufacturing, and food production. The screen's robust design maintains its integrity even under high-pressure applications, while its smooth surface prevents material buildup and facilitates easy cleaning and maintenance. Additionally, the 230 mesh screen's versatility extends to various mounting configurations, enabling seamless integration into existing filtration systems or new equipment designs.