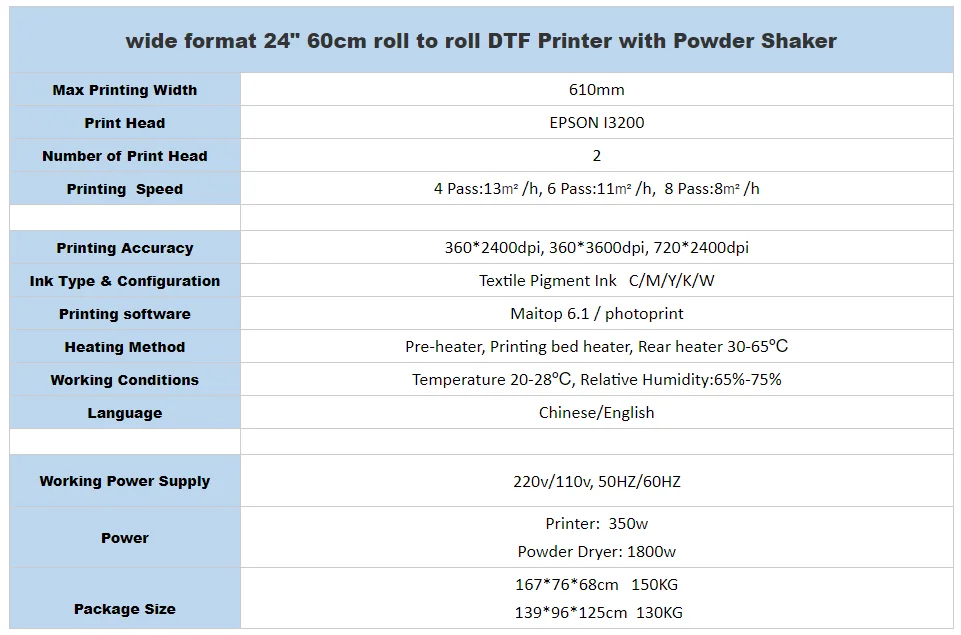

24 Inches I3200 Heads Dtf Printer and Powder Shaker Machine with 9 Multi-Color Fluorescent Printing

This 24inch DTF Printer with I3200 heads suited for business with heat transfer is highly efficient to high-quality process, custom-printed textiles. Sod white ink circulation system to avoid clogging. Integrated dryer for effective heat treatment.

- Overview

- Recommended Products

24 Inches i3200 heads Dtf Printer and Powder Shaker Machine with 9 Multi-Color Fluorescent Printing

Our New Model DTF printer , can print CMYK FG FM FO FY W, 9 Multi-color Printing

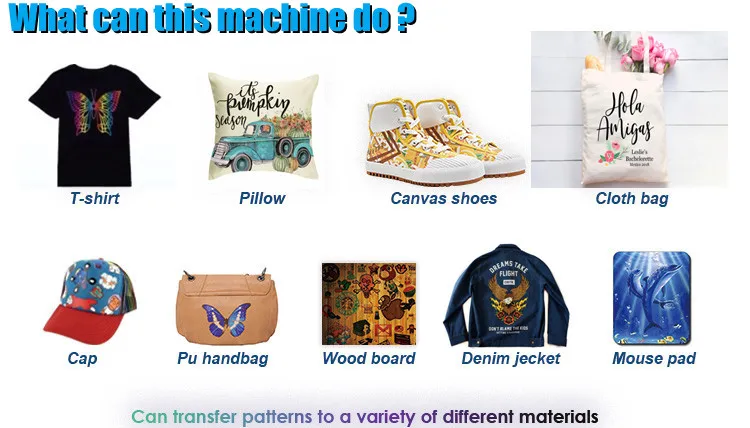

DTF is the latest print transfer technology for all fabric prints.

DTF ink is transferred to film, and then through the powder, shaking and hot pressing,

finally attaches to the whole fabric to be printed.

Low cost and easy operation, it can solve the problem that the DTG machine cannot print.

We have everything you need to get started with Direct to Film printing!!!

DTF ink is transferred to film, and then through the powder, shaking and hot pressing,

finally attaches to the whole fabric to be printed.

Low cost and easy operation, it can solve the problem that the DTG machine cannot print.

We have everything you need to get started with Direct to Film printing!!!

Epson Print Heads Optional

• I3200/4720 Original Print Heads • High densty and longer service life

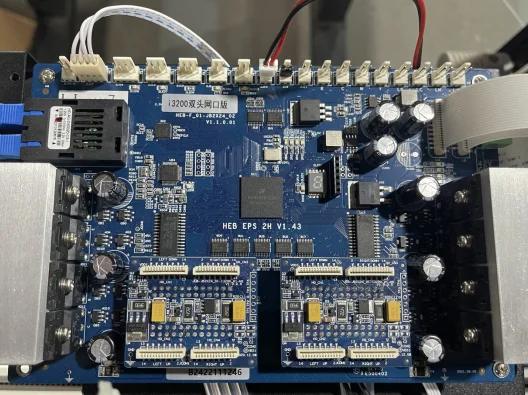

Hoson Main Board

• More fuctions• Operation more convenient and stable

Ink Cartridge System & Alarm Device

• Support CMYK LcLm W• Large capacity for constant pressure ink supply• Alarm device to avoid ink shortage

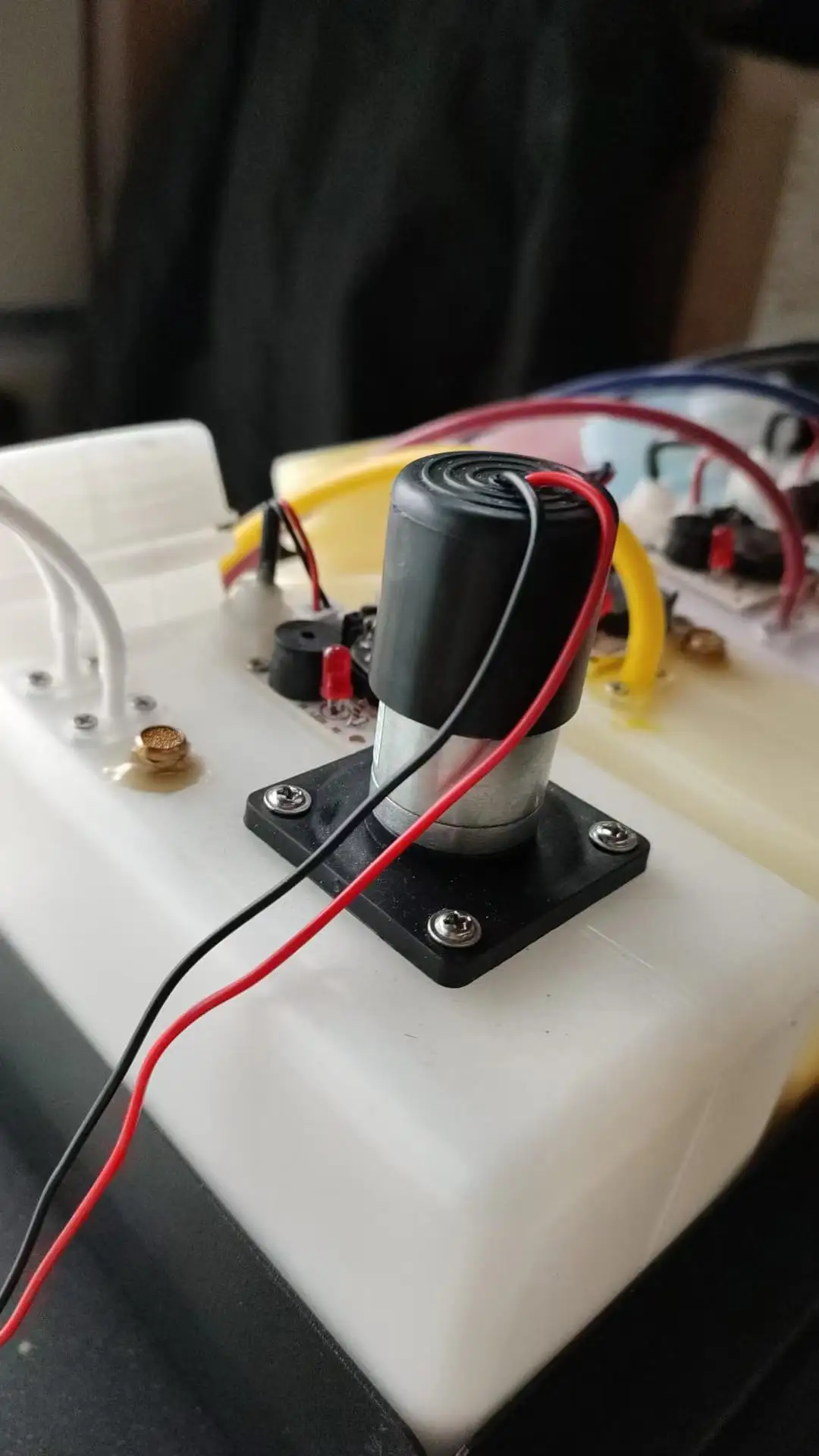

White ink Stirring

• Automatically and intermittently stirs the white ink• Keep printing color uniform• Keep the nozzle unclogged

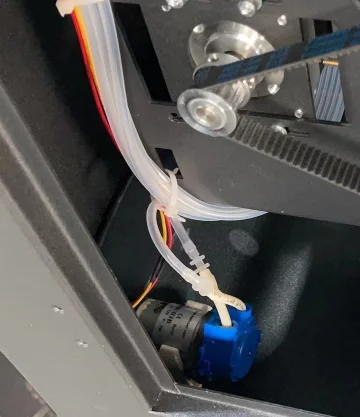

White ink Circulation

• Attached with circulating pump,

• circulate the ink in the pipeline to prevent blockage

White ink Stir & Circulation

• Seperate button

• Stir and circulation can be adjusted

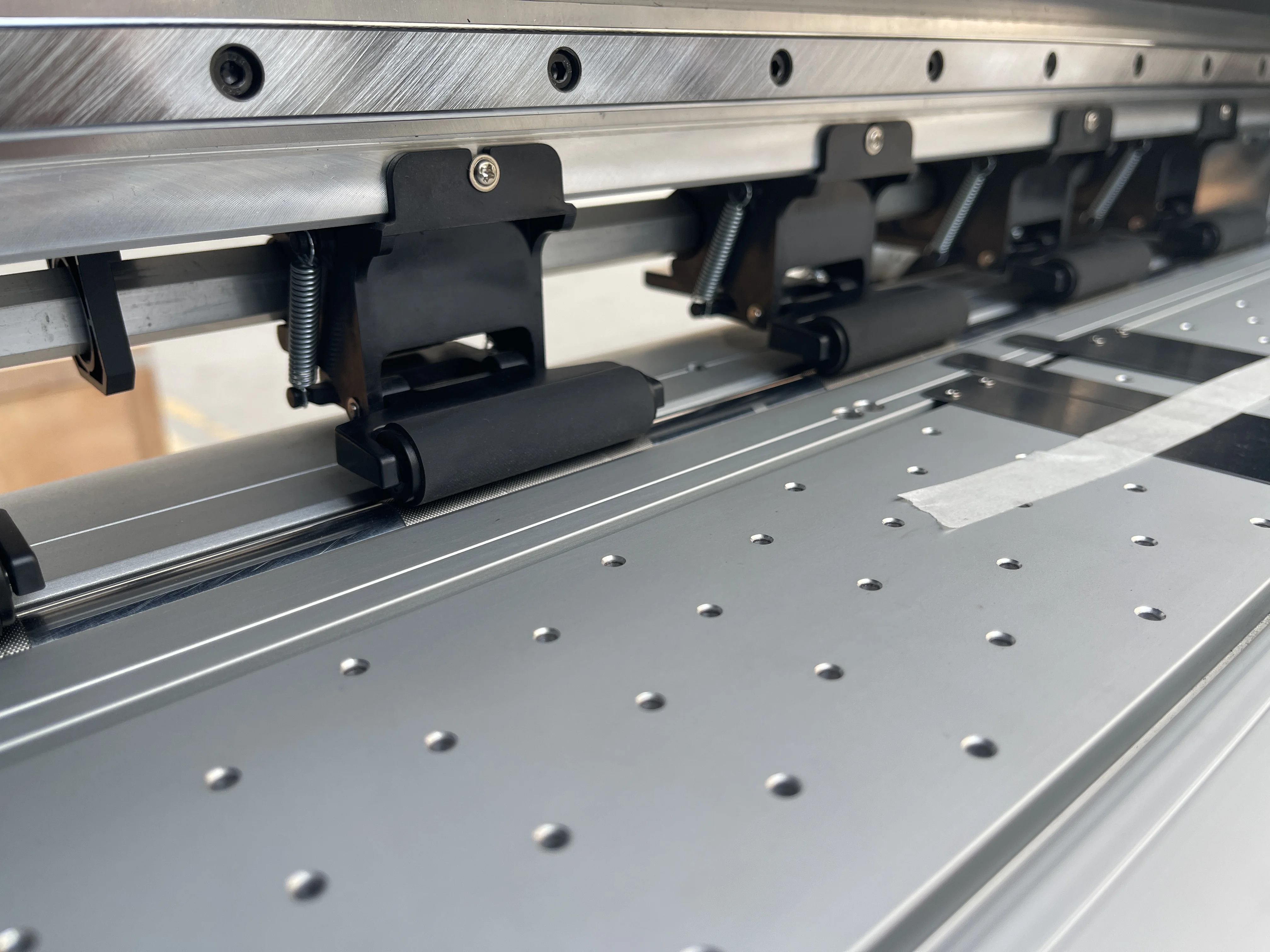

Japan THK Linear Guide Rail

• Front and rear arc plate heating • 3-way constant temperature

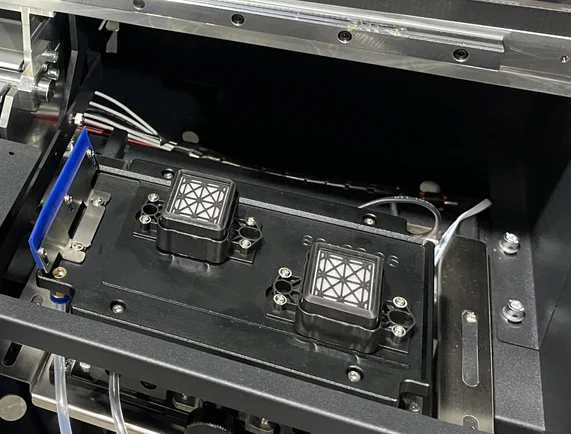

Elevation Capping Station

• Protect print heads• Lifting ink stack, more accurate and durable

Suction Platform

• Ensure material flatness• Improve smoothness of paper feeding • Ensure stability of printing

Temperature Control Panel

• Front and rear arc plate heating • 3-way constant temperature

The DTF process is as simple in its working as its name suggests -

Print on a film and directly transfer onto fabric.

1. Design Pattern Use photoshop, illustrator or other software to design your pattern2. Print your design Ajust the printer parameters in the RIP sofware and use ink to print your pattern to the film3. Powdering Turn on the switch of powder shaking machine, the machine will automatically powdering, shaking , drying and fix the color4. Heat Press Use a heat press machine, set the temperature to 150 degree, and time 12 seconds to transfer