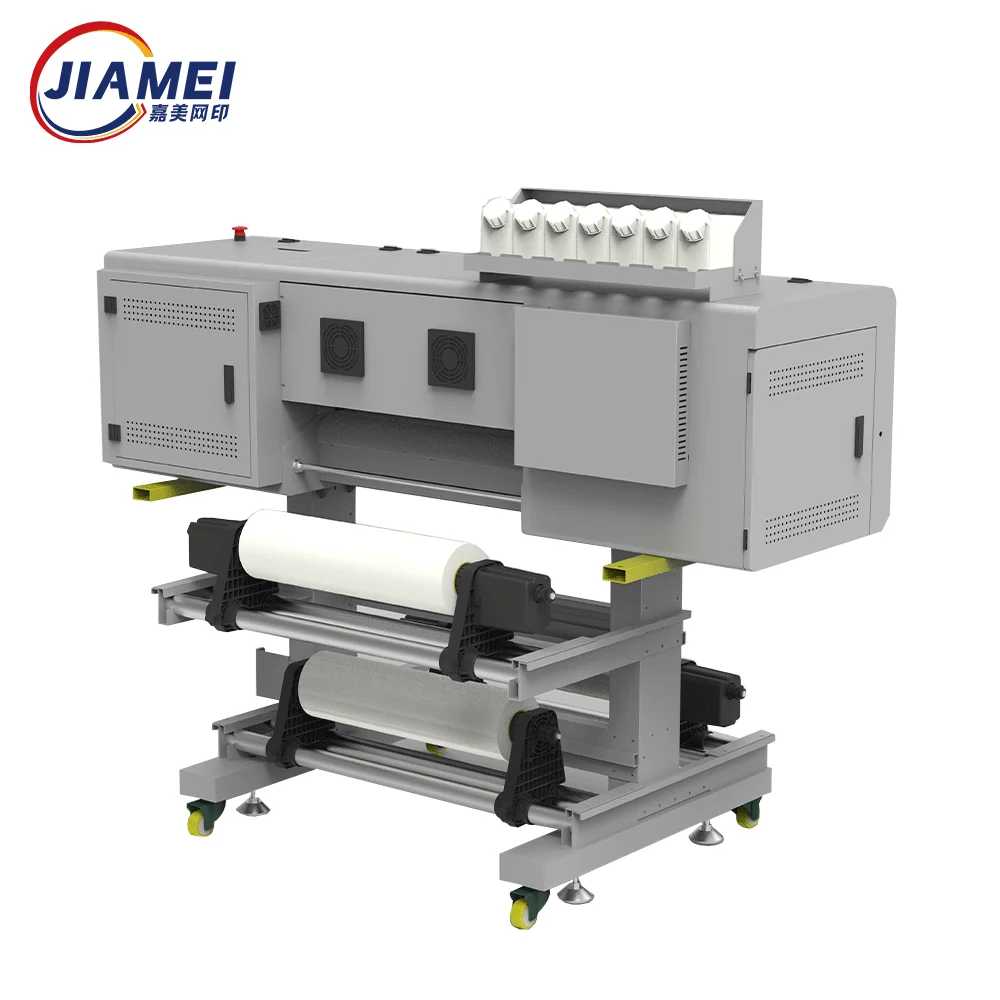

Hot Sale I3200 Printheads Dtf Uv Printer 60cm ab Film Printer Roll to Roll Uv Printing Machine

Provides roll-to-roll printing without interruption with a maximum print width of 60cm (24 inches), making it perfect for mass production. Allows for printing and laminating to occur in a single step, minimizing manual labor and maximizing productivity.

- Overview

- Recommended Products

The uv dtf printer is a uniquely designed printer, which uses the AB film as a carrier to print the pattern on the A film, and then attaches the B film through the laminating device, and the ink is quickly solidified by the UV lamp, so that our pattern printing is completed.

After that, the pattern is cut out by a cutting machine, the pattern is glued on the substrate, and the film is torn off to complete the printing.

It has simple printing steps, wide application, adjustable size, short time and good effect.

Print Head

|

three head |

Hoson board I3200-U1 |

|

Speed

|

4 pass: 6.5-10 m²/h |

6 pass: 5.8-7 m²/h |

|

Medium Width |

600MM |

Printing Medium |

UV special AB film |

Ink Type |

Special environmental protection UV ink |

Ink Capacity |

500ML |

Print Interface |

Gigabit network interface |

Working Environment |

Temperature: 15-30℃ Humidity: 40-80% |

Power Requirement |

AC 220V 50HZ/60HZ 7.5KW |

Power Supply |

220V/110V |

Print Height |

Adjustable height 0~6MM |

Machine Size |

1900mm*1000mm*1500mm 110KG |

Machine Package Size |

1960mm*1070mm*750mm 150KG |

Automated Operations

In the process of using the printer, there will be no complex operation that we need to control.

Automatically feed the A film, Start the printing, Automatically laminating and collect finsh printed prints.

High Precision & Printing Speed

We can offer different printheads, Print faster and Manipulate easier.

Intelligent ink detection

Printing and laminating arecompleted at one time, eliminating the laminating machine;

High Precision & Printing Speed

We can offer different printheads, Print faster and Manipulate easier.

Control Panel & Heating system & Vacuum platform

The control screen panel is easy to operate and understand.

The temperature can be adjusted manually.

The vacuum platform can fix the film, and the printing process is not offset.

After printing, automatic heating and pressure cover B film.

Intelligent ink detection

Hoson Main board, high precision, fast speed, bright and delicate printing screen

High precision motors and guides

We will provide you instant online support service and free repair service.

We will provide you instant online support service and free repair service.

Let's see the printing process of UV DTF printing:

1.Print the pattern on the direct transfer film first, and print in the order of white ink. color ink, & varnish.

2.After printing,put the PET film on the direct transfer film. It is recommended to use a laminating machine to press it. Of course, it can also be operated manually.

3.Cut out the desired pattern and paste it on the material to be pasted.

4.Press the pattern repeatedly, slowly tear open the film,finished.

1.Print the pattern on the direct transfer film first, and print in the order of white ink. color ink, & varnish.

2.After printing,put the PET film on the direct transfer film. It is recommended to use a laminating machine to press it. Of course, it can also be operated manually.

3.Cut out the desired pattern and paste it on the material to be pasted.

4.Press the pattern repeatedly, slowly tear open the film,finished.