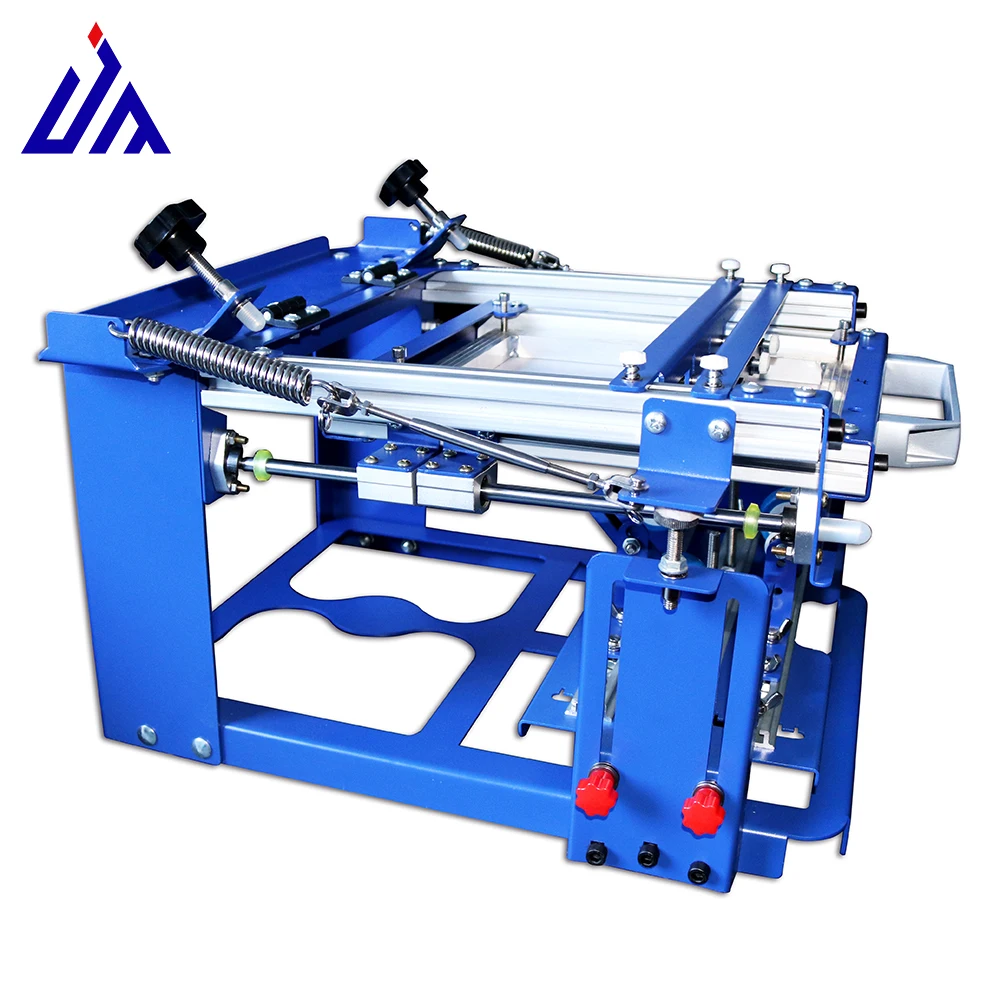

Manual Silk Carousel Serigraphy Screen Printing Equipment Machine Bottle

When you look for printing devices, this Manual Silk Carousel Serigraphy Screen Printing Machine can meet your requirements by providing fast screen print on cylindrical bottles and any round products.

- Overview

- Recommended Products

Product Description

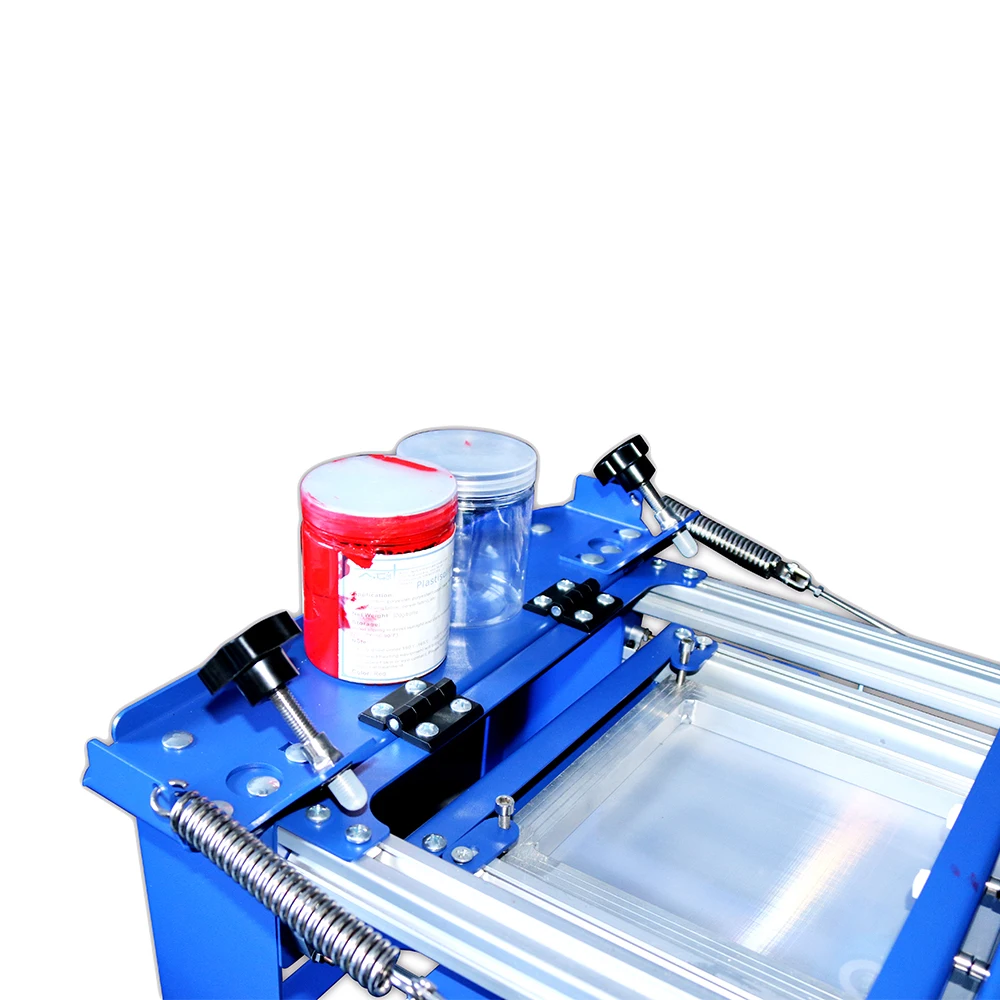

This machine adopts the printing screen frame height positioning structure, the front part is equipped with the parallel placement plate, the whole machine is firm and stable in the printing process. Printing materials and tools such as ink buckets can be placed on the rear horizontal board of the main machine.

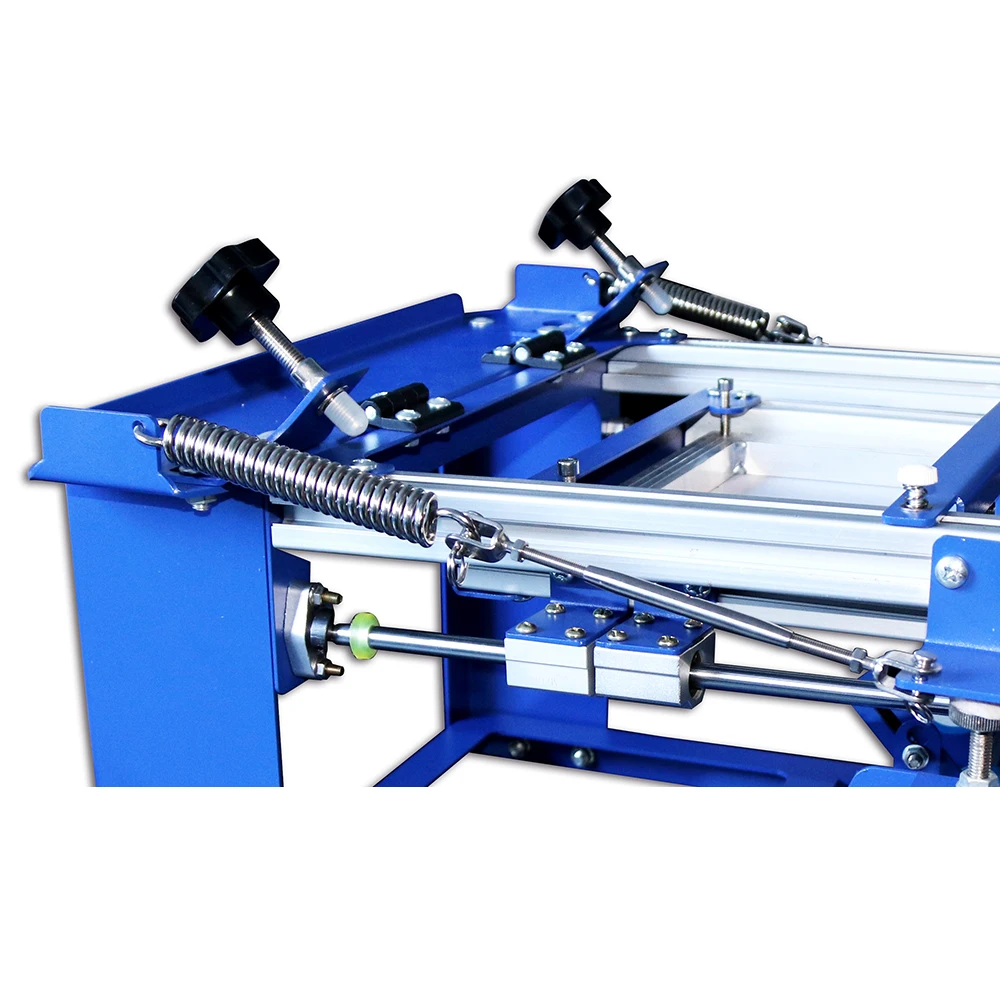

The printing plate frame uses the spring to pull and lift, matches the flower basket screw to adjust the lift strength of the screen plate , the lift angle of the screen plate can be controlled by adjusting knob, the operation is easier. The spring tension on both sides of the machine should be as consistent as possible after installation , otherwise it may cause distortion of the printing screen frame.

Spring Installation Method

It is easy to install and remove the screen frame. Just put the screen plate into the back support plate from below of the printing plate rack, and then put the screen plate into the front support plate, tighten the screen plate fixing screw. (limited to the design requirements of the machine, the screen board of the machine must use the screen frame with the outer diameter of 300*235 mm and the height within 30 mm.) 2 screen frames are attached to the machine.

Installation Methods of the Screen Plate

Place the screen frame into the rear support plate from the bottom of the installation table.

Move the front of the frame to the front support plate, tighten four Screws to fix the screen frame.

4 sliders connected to the optical axis to make the screen frame slide back and forth,it is easy and smooth to push and pull .

Specification

Model |

JM-MCP1012 |

Diameter |

<80mm |

printing patterns width |

<=140mm |

Length |

<=160mm |

screen plate outer diameter |

<=300*235mm |

Thickness |

<=30mm |

Packing Size |

59x55x39 cm by wooden case |

Product Application

Curved screen printing machine is mainly used for printing cylindrical type, cone type products; Such as a variety of plastic, glass, metal materials made of cylindrical, conical shape products, including wine bottles, medicine bottles, cosmetics bottles and other packaging bottles; Mugs, thermos mugs, beer mugs, red mugs, etc. Glass tube, pen ,ballpoint pen, fishing rod, bat and other small cylindrical products; Pure bucket, paint bucket, alcohol bucket, paint bucket, oil and lubricating oil bucket and other large packaging cylindrical products.