30cm Roll to Roll UV DTF Film Rolls UV AB Film for Phone case Wood Bottle Paper

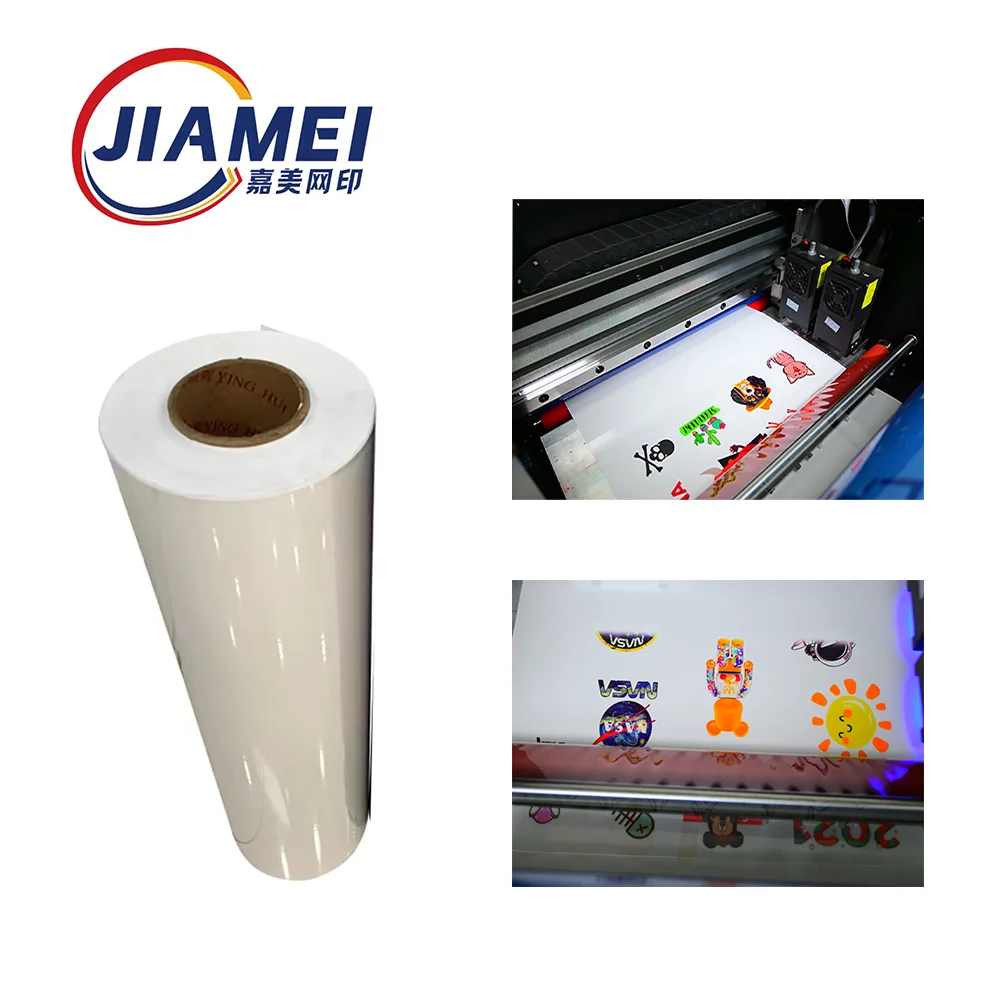

Designed with versatility in mind, our 30cm Roll to Roll UV DTF Film Rolls (UV AB Film) is ideal for high-quality printing applications, particularly on materials such as phone cases, wood bottles, and paper products.

- Overview

- Recommended Products

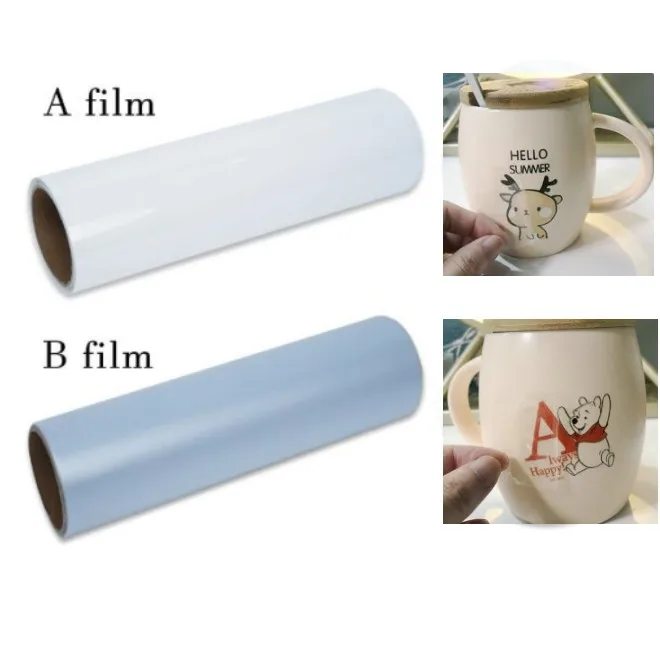

UV DTF Film is constructed with new technology, such as using two pieces of film A and B together, without heating and powder shaking.

It can not only print on flat, wood, ceramic, glass, metal, acrylic and other materials, but also print on curved and cylindrical objects, and output good 3D textures, high color fastness and scratch-resistant printing effects.

It can not only print on flat, wood, ceramic, glass, metal, acrylic and other materials, but also print on curved and cylindrical objects, and output good 3D textures, high color fastness and scratch-resistant printing effects.

Product name |

UV DTF PET Film |

Brand |

JM-UV AB Film |

Material |

PET Film |

Usage |

Printing Film |

Transparency |

Transparent |

Size |

30cmx100m, 60cmx100m |

Quality |

Excellent |

1. High transparency, thick, self-adhesive, hard, scratch-resistant, high-temperature resistant, long-lasting,non-fading, non-yellowing, and UV-resistant.

2. Environmental protection, waterproof and wear-resistant, colorful, good 3D texture, simple operation, easy to paste, can paste any material (except fabric)

1. UV film is an active free radical or ionic group generated by adding a photoinitiator or photosensitizer to a specially formulated resin, and through UV absorption and light curing through UV equipment.

2. It converts UV coatings, inks, adhesives(resins), etc. from liquid to solid within seconds by initiating polymerization, cross-linking and grafting reactions.

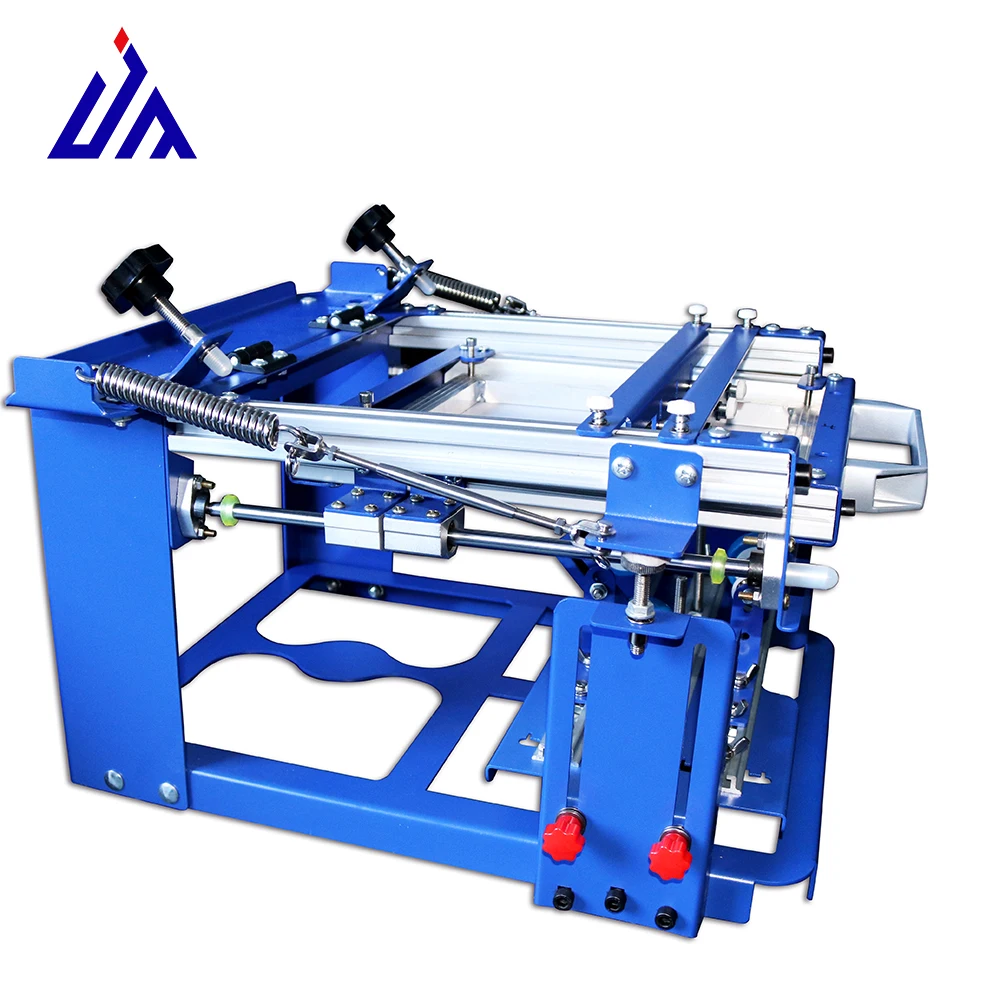

The uv dtf printer has a printing device and a laminating device, and requires AB film as a printing carrier to ensure the entire printing process.

1. Printing patten with A film

2. Through the lamination device.pattern separation with B-membrane

3. Press the film and tear off film

2. Through the lamination device.pattern separation with B-membrane

3. Press the film and tear off film