dtf film printing

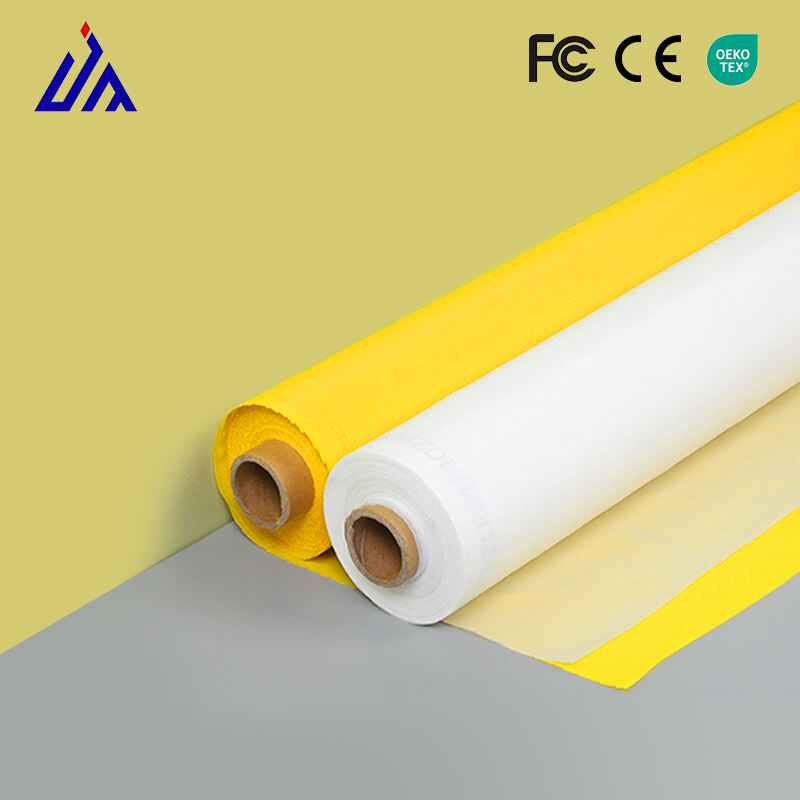

DTF (Direct to Film) printing represents a groundbreaking advancement in textile decoration technology, offering a versatile solution for creating high-quality transfers that can be applied to various fabric types. This innovative process involves printing designs directly onto a specialized PET film using specially formulated DTF inks, followed by the application of hot-melt adhesive powder. The printed design is then cured and ready for heat transfer onto the desired garment. The technology employs water-based inks that provide exceptional color vibrancy and wash-fastness, ensuring long-lasting results. What sets DTF printing apart is its ability to handle intricate designs and gradients with remarkable precision, while maintaining excellent opacity on both light and dark fabrics. The process is particularly notable for its compatibility with a wide range of materials, including cotton, polyester, nylon, silk, and leather. Unlike traditional transfer methods, DTF printing doesn't require any pretreatment of garments and can produce transfers that are both flexible and durable. The technology has found widespread applications in custom apparel production, promotional merchandise, and small-batch manufacturing, making it an invaluable tool for businesses of all sizes in the textile printing industry.